Deguisa’s history

1966: Foundation of Deguisa, De Guinea Sociedad Anónima, by the Guinea family, owner of the manufacturer of industrial furnaces Guinea Hermanos Ingenieros SA.

1974: Construction of the Amurrio plant for the assembly of FLOCON sliding valve system and its commercialization in the national market.

1975: Representation agreement of the American manufacturer of high voltage vacuum switches JOSLYN in Spain.

1975: Representation agreement of the refractory product manufacturer HARBISON WALKER in Spain and Portugal.

1982: Under license manufacturing and sale agreement of the North American burner manufacturer NORTH AMERICAN MFG. COMPANY.

1983: Under license manufacturing and sale agreement of the manufacturer of formed by pouring products ZIRCONAL PROCESSES LTD.

1984: Under license manufacturing and sale agreement of refractory products of the Swedish manufacturer SVENSKA FORSHAMMARS.

1988: Representation agreement of the manufacturer of industrial control instrumentation BARBER COLMAN in Spain.

1989: Installation of the first combustion system with regenerative burners ON an aluminium melting furnace at the INESPAL factory in Amorebieta.

1990: Under license manufacturing and sale agreement of bricks for the glass industry of the German manufacturer SORG.

1993: Representation agreement of the filter manufacturer for SELEE LTD casting in Spain.

1995: Design of the new NOVALCO sliding valve system.

1996: Implementation of the quality assurance system according to ISO 9001.

1997: Under license manufacturing and sale agreement of refractory manufacturer LAFARGE.

2003: Investment in a PRECAST product manufacturing facility.

2004: Agreement for the distribution and sale of silica-based products manufactured by the Swedish company CALDERYS NORDIC AB.

2007: License FOR manufacturing and sale of the Novalco system to ORL in India.

2009: Incorporation of a 3200 Tn press for shaped product of large formats.

2016: Commemoration of the 50th anniversary.

2017: Concentration of ownership in the third generation of industrial engineers of the Guinea family.

2020: ISO 14001:2015 certification for environmental management systems.

2021: Certification of the occupational health and safety system according to the ISO 45.001 standard.

Our identity by Nestor Basterretxea

Nuestra identidad por Nestor Basterretxea

Production capacities

Deguisa has 7,000 m² facilities where there are a production area of pressed refractories, shaped and unshaped refractories, another for the manufacture of precast pieces, a workshop for the manufacture and assembly of mechanical elements, laboratory, offices and general wharehouse.

The equipment that configures the production means includes; high intensity mixers, hydraulic presses, drying and cooking ovens that can reach temperatures up to 1,800º c, grinders, blasting machines, recovery mills and a vacuum pitch impregnation plant

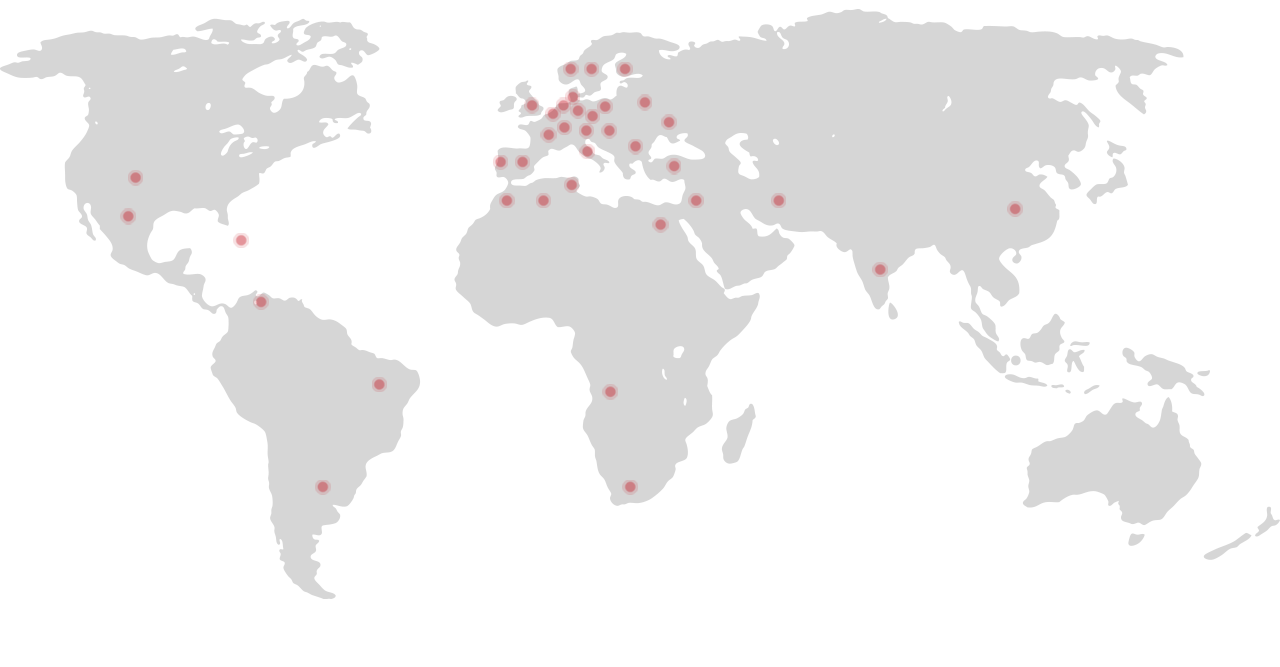

Presence of Deguisa in the world

R&D&i

Deguisa has highly qualified personnel and a laboratory equipped with the following devices: high temperature oven, intensive mixer, abrasion test and MOR.

Deguisa develops its own products and in some estrategical projects requesting support of first level technology centers. Also participates in different research projects collaborating in national and international consortiums.

Projects

Deguisa anually participates in Research, Development and Innovation projects with the financial support from the European Regional Development Fund (FEDER), from the European Union, and the Basque Government.

Global management system

The market where Deguisa is present demands strict requirements regarding products and services. To meet these requirements, Deguisa has developed a management system based on the certification of its quality, environmental and occupational health and safety systems in accordance with ISO 9.001, 14.001 and 45.001 standards.

Deguisa is committed to a global management system present in all areas and departments of the company.

Management system is continuously updated, by the requirements of the standard as a consequence of the improvements carried out internally, always taking into account all the interested parties. The scheme, planning, doing, validating and acting guides the management policy at Deguisa.

DOWNLOAD ISO 9001 - 14001 - 45001 certificates

DOWNLOAD management policy

Contributions

Deguisa is an active member of the associations and reference projects within the sectors in which takes part.

Deguisa fulfill the necessary requeriments to be considered as an Innovative SME by the Spanish Ministry of Science and Innovation.